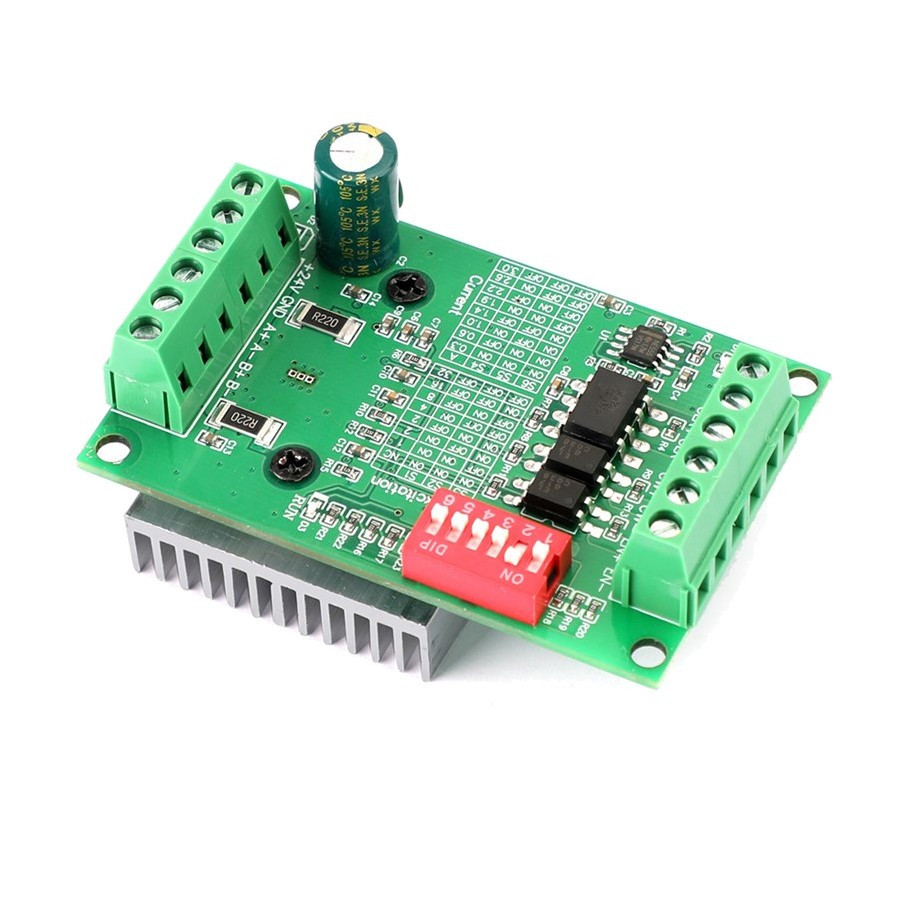

CNC Router Single Axis 4.5A TB6600 Stepper Motor Driver

Original price was: 900.00 EGP.790.00 EGPCurrent price is: 790.00 EGP.

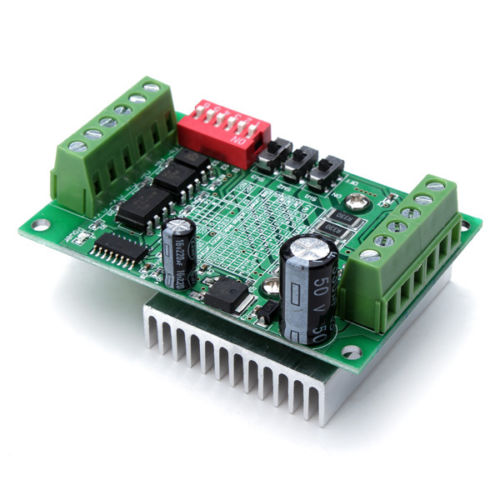

The TB6600 Stepper Motor Driver is a powerful and reliable driver module specially designed for CNC routers, 3D printers, and other motion control systems. With support for up to 4.5A output current and wide voltage compatibility, this single-axis driver is capable of driving 2-phase and 4-phase hybrid stepper motors with high precision and efficiency.

Based on the Toshiba TB6600HG chip, this module delivers stable performance, low noise, and excellent heat dissipation, making it ideal for professional-grade stepper control applications. It supports microstepping up to 1/32 and has built-in overheat, overcurrent, and short-circuit protection.

Description

CNC Single Axis TB6600 Stepper Motor Driver – 4.5A

The CNC Single Axis TB6600 Stepper Motor Driver (4.5A) is a high-performance driver designed for precise control of stepper motors in CNC machines, 3D printers, and automated equipment. This single-axis driver offers reliable operation, smooth motion, and adjustable current settings, making it ideal for hobbyist and professional CNC projects.

Built around the TB6600 integrated circuit, this driver provides stable microstepping, overcurrent protection, and thermal safety, ensuring efficient and accurate motor control. Its compact design allows easy installation in CNC routers, laser engravers, and other stepper motor applications.

Whether you are setting up a single-axis CNC machine, upgrading a 3D printer, or experimenting with robotics, the TB6600 stepper driver delivers consistent performance and precision motion control.

Key Features of CNC Single Axis TB6600 Stepper Driver

-

Current Rating: Adjustable up to 4.5A, suitable for NEMA 17, 23, and similar stepper motors.

-

Microstepping Support: Offers full, half, quarter, eighth, and sixteenth microsteps for smooth motion.

-

Single Axis Control: Dedicated to one stepper motor for precise independent control.

-

Input Voltage: 9–42V DC, compatible with most CNC setups.

-

Overcurrent & Overheat Protection: Protects the driver and motor from damage.

-

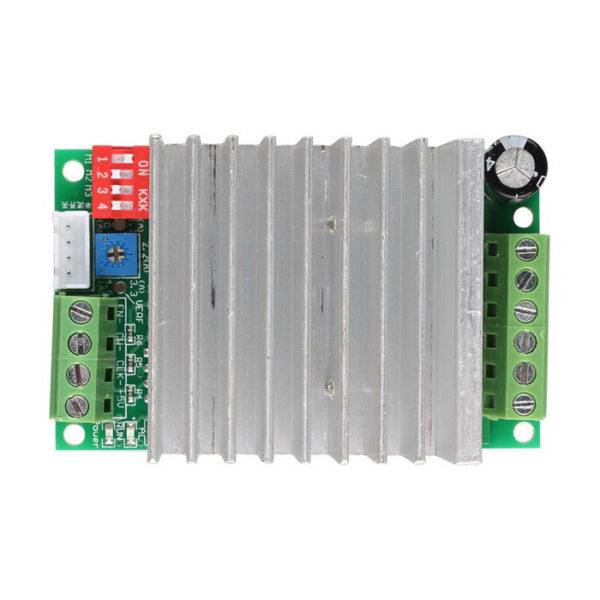

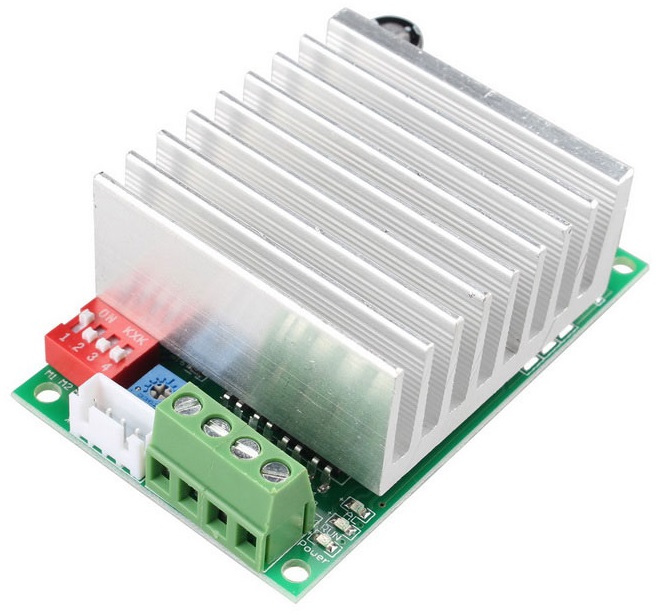

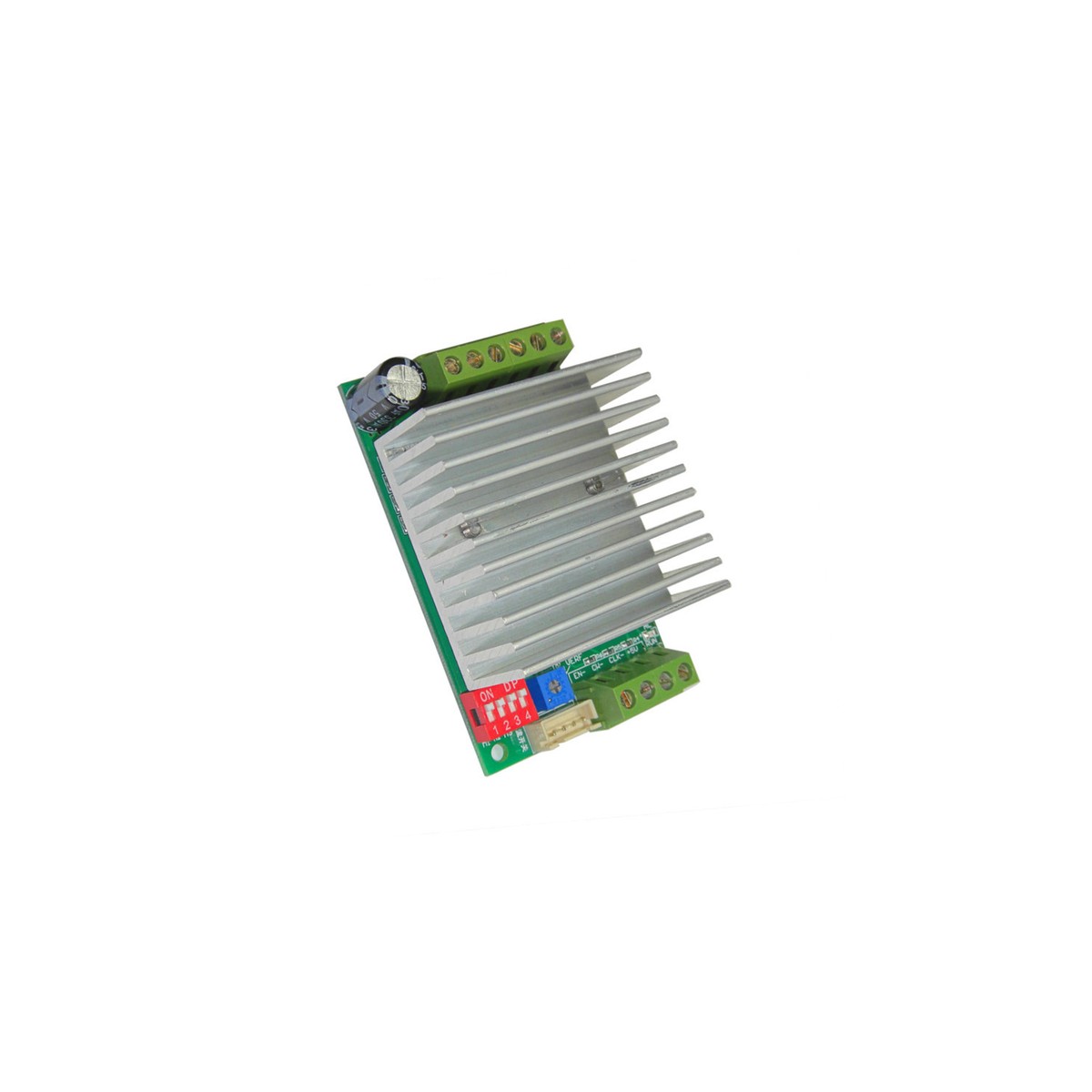

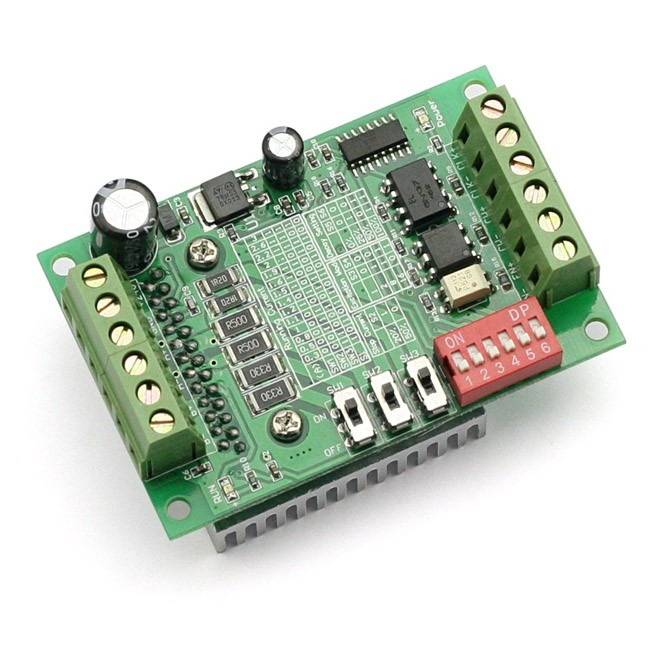

Easy Configuration: DIP switches for microstepping and current adjustment.

-

Compact Design: Space-saving layout for CNC machine integration.

-

Stable Performance: Smooth, quiet, and vibration-free operation.

-

Wide Applications: Suitable for CNC routers, 3D printers, laser engravers, and automation systems.

Technical Specifications

-

Driver IC: TB6600

-

Current Rating: 0.5–4.5A (adjustable)

-

Supply Voltage: 9–42V DC

-

Microstep Resolution: 1, 1/2, 1/4, 1/8, 1/16

-

Pulse Input Frequency: Up to 200 kHz

-

Interface: Step and Direction inputs

-

Protection: Overcurrent, short-circuit, thermal protection

-

Operating Temperature: -20°C to +70°C

-

Dimensions: Compact PCB suitable for enclosure mounting

Why Choose the TB6600 Stepper Motor Driver?

-

Precise Motor Control – Microstepping support ensures smooth, accurate motion in CNC machines and 3D printers.

-

High Current Capacity – Supports up to 4.5A, ideal for high-torque stepper motors.

-

Reliable Protection Features – Built-in thermal and overcurrent protection ensures long-lasting performance.

-

Easy to Use – Simple DIP switch configuration for microstepping and current settings.

-

Versatile Applications – Perfect for CNC routers, laser engravers, 3D printers, and automation systems.

Applications of CNC Single Axis TB6600 Stepper Driver

-

CNC Routers: Precise control for single-axis motion in milling and engraving machines.

-

3D Printers: Drive X, Y, or Z-axis stepper motors with smooth motion and minimal vibration.

-

Laser Engravers: Accurate positioning of laser modules for high-quality engraving.

-

Automation Systems: Control linear actuators, conveyors, or robotic arms in industrial setups.

-

Robotics Projects: Independent stepper motor control for robotic joints or mechanisms.

-

DIY CNC Projects: Ideal for hobbyist CNC machines and electronics projects.

How to Use the CNC Single Axis TB6600 Stepper Driver

-

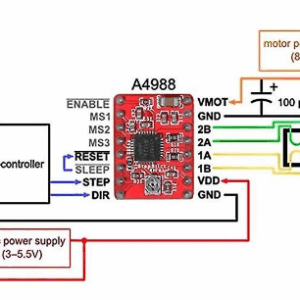

Connect Power Supply – Provide a DC voltage within 9–42V to the driver’s power input.

-

Connect Stepper Motor – Wire the motor’s A+, A-, B+, B- terminals to the driver.

-

Configure DIP Switches – Adjust the microstepping mode and current limit according to motor specifications.

-

Connect Control Signals – Wire the Step and Direction pins to your microcontroller, CNC controller, or driver board.

-

Test Motion – Apply pulses from the controller to verify smooth motion and correct rotation direction.

-

Integrate into Machine – Mount the driver and motor in the CNC machine, 3D printer, or robotic setup.

With this setup, the TB6600 driver provides accurate, smooth, and reliable single-axis control for various stepper motor applications.

Package Includes

-

1 × CNC Single Axis TB6600 Stepper Motor Driver – 4.5A

Conclusion

The CNC Single Axis TB6600 Stepper Driver (4.5A) is a high-performance, compact, and reliable solution for driving stepper motors in CNC, 3D printing, laser engraving, and automation projects. Its adjustable current, microstepping support, and built-in protections make it suitable for both hobbyists and professional engineers.

Whether you are building a single-axis CNC router, upgrading a 3D printer, or developing an automated system, this TB6600 driver ensures smooth, precise, and safe motor control, making it an essential component for modern stepper motor applications.

Reviews

There are no reviews yet.