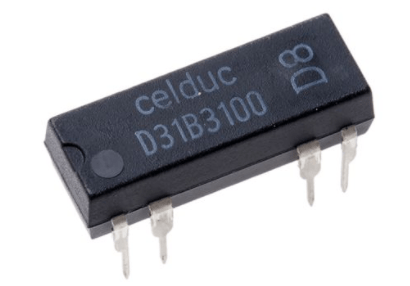

D31B3100 Celduc Reed Relay

16.50 EGP

D31B3100 Celduc Reed Relay 5VDC 500Ohm 0.5A.

Out of stock

Description

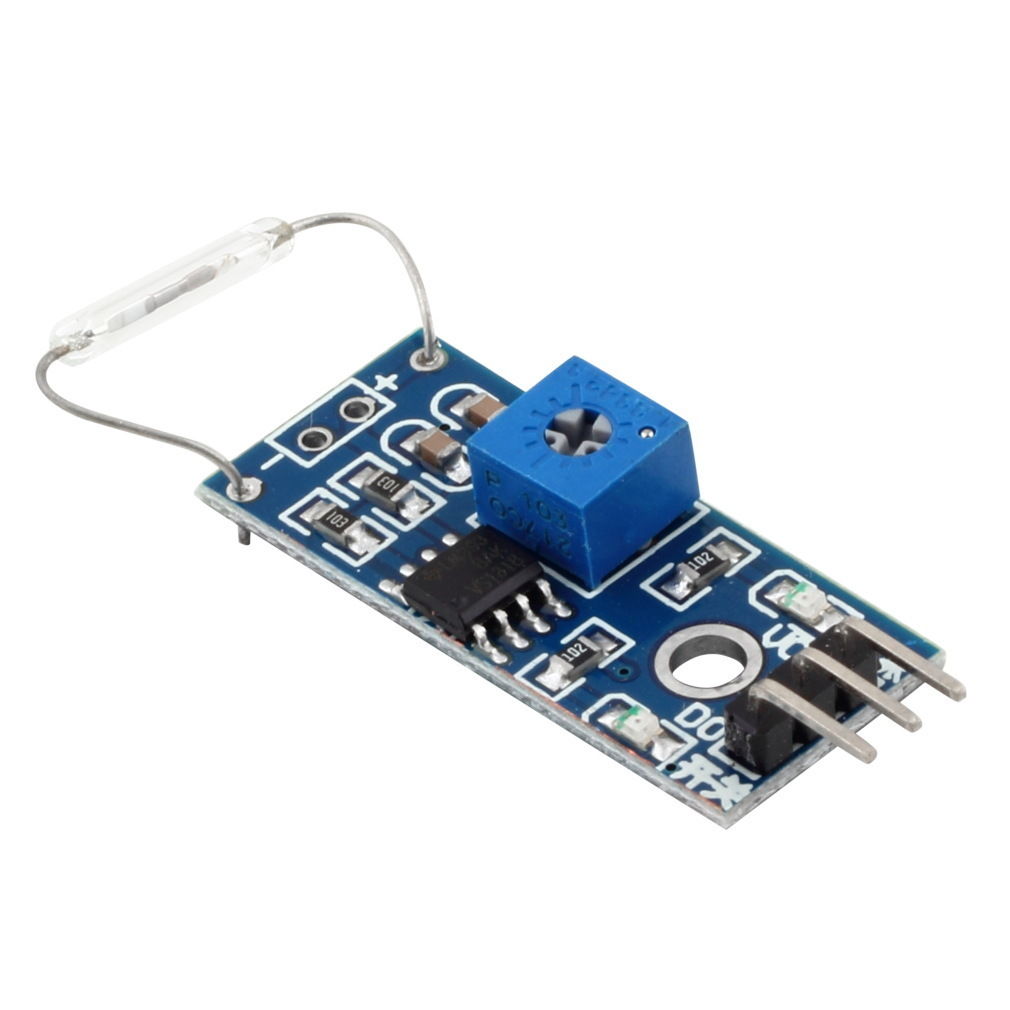

- A reed relay is a type of relay that uses an electromagnet to control one or more reed switches.

- The contacts are of magnetic material and the electromagnet acts directly on them without requiring an armature to move them

- Reed relays are small and fast acting.

- They require a much lower level of power to actuate them than other traditional types of relay and as a result they find many uses in various forms of electronic circuits.

- In addition to this, reed relays or reed switches can be made much smaller than traditional forms of relays, although their current capability is less, but they still provide an attractive proposition in many instances.

- A further advantage of reed relays is that they can offer higher levels of reliability than other relays because of their simplicity and few moving parts, but still being mechanical, they are not always as reliable as fully solid state relays and switches.

- A reed switch consists two reed contacts, typically made from nickel-iron and then plated with materials to ensure the maximum life to the device.

- The reed contact materials used include ruthenium, rhodium and sometimes iridium or where high voltages are involved it might be tungsten or molybdenum.

- Often rhodium is usually electroplated onto the reed element, whereas ruthenium is generally sputtered.

- Reed relay works by placing a magnetic field close to the reed switch contacts.

- This causes each of the reeds to become magnetically orientated such that the two ends of the reed attract each other and move together closing the contact.

- Under conditions where no magnetic field is applied, the two contacts will not be magnetically orientated and the spring loading in the contacts will keep them apart.

- As a magnetic field, for this explanation a bar magnet is shown and although this is not normally used it will work well.

- As the magnets is brought closer to the reed contacts which are made of a magnetic material, typically nickel iron, this starts magnetically orientated the two reed relay contacts.

- A north pole will appear in one contact and a south in the other.

- As the magnetic field close to the contacts increases, so too does the strength of the magnetization of the contacts.

- Ultimately a point is reached where the magnetic attraction starts to overcome the spring in the contacts.

- As the contacts move nearer, so the strength of the attraction increases progressively increases, and so a firm contact is ultimately made.

- However the speed with which the reed switch contact approach one another does mean that contact-points collide with considerable energy so that they rebound, collide again etc for a while causing a phenomenon called contact bounce.

- The way in which the contacts bounce depends largely upon the size of the reed switch, the weight of the contact-elements, their elasticity, etc.

- Obviously the bounce period significantly increases the wear of contact-elements.

- The contact bounce can give rise to arcing if current is being carried, especially if there is a capacitive or inductive element to the circuit being switched.

Package Included:

- 1 X D31B3100 Celduc Reed Relay

Reviews

There are no reviews yet.