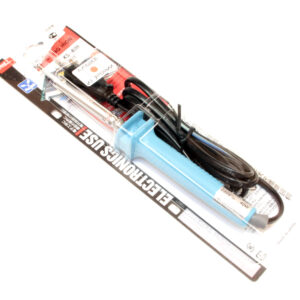

Solder Wick CP-2015 for maintenance 2.0mm

35.00 EGP

The CP-2015 Solder Wick is a high-quality desoldering braid designed for efficient solder removal during PCB repairs, rework, and component replacement. With a 2.0mm width, it’s ideal for precise desoldering of through-hole components, SMD pads, and fine-pitch ICs without damaging circuit boards.

Description

Key Features:

✔ Premium Copper Braid – High-purity, oxygen-free copper for maximum solder absorption.

✔ 2.0mm Width – Perfect for small to medium solder joints (e.g., resistors, capacitors, IC legs).

✔ Flux-Infused – Pre-coated with rosin flux for faster, smoother solder wicking.

✔ High Heat Resistance – Withstands repeated use with a soldering iron (up to 450°C).

✔ Tangle-Free & Flexible – Easy to handle and cut to desired lengths.

✔ No Residue – Clean removal with minimal flux leftovers (easy to clean with IPA if needed).

✔ Reusable – Can be trimmed and reused multiple times (until fully saturated).

Applications:

-

PCB Repair & Rework – Remove excess solder from pads and vias.

-

Component Replacement – Desolder ICs, transistors, connectors, etc.

-

SMD Rework – Clean up bridged solder on fine-pitch components.

-

DIY Electronics & Hobby Projects – Fix soldering mistakes effortlessly.

How to Use:

-

Place the braid over the solder joint.

-

Heat with a soldering iron (300–350°C recommended).

-

Let the solder melt and flow into the wick via capillary action.

-

Lift away the braid once saturated.

-

Trim used sections for a fresh end.

Why Choose CP-2015?

✅ Faster than solder suckers – No moving parts, better precision.

✅ Gentler on PCBs – Reduces risk of pad lifting vs. vacuum tools.

✅ Cost-effective – Long-lasting spool for frequent repairs.

Package Includes:

-

1x Solder Wick CP-2015 (2.0mm width, 1.5m length) (or custom quantity).

Reviews

There are no reviews yet.